-

Natural Diamond Core Bit

Product code:DNC201

IADC:M712

Drilling in medium to hard formations.

It is suitable for coring in medium to hard formations with a certain degree of abrasive formation.

-

Micro Core Bit

It is suitable for coring operations in medium and hard formation with long life time feature.

-

Centralizer

The centralizer is mainly composed of rubber and reinforced metal rubber, which is used in different measuring systems while drilling. We study and evaluation of elastic materials and bonding forces between metals to design a professional rubber centralizer that can be able to meet the needs of customers for measuring tools while drilling.

-

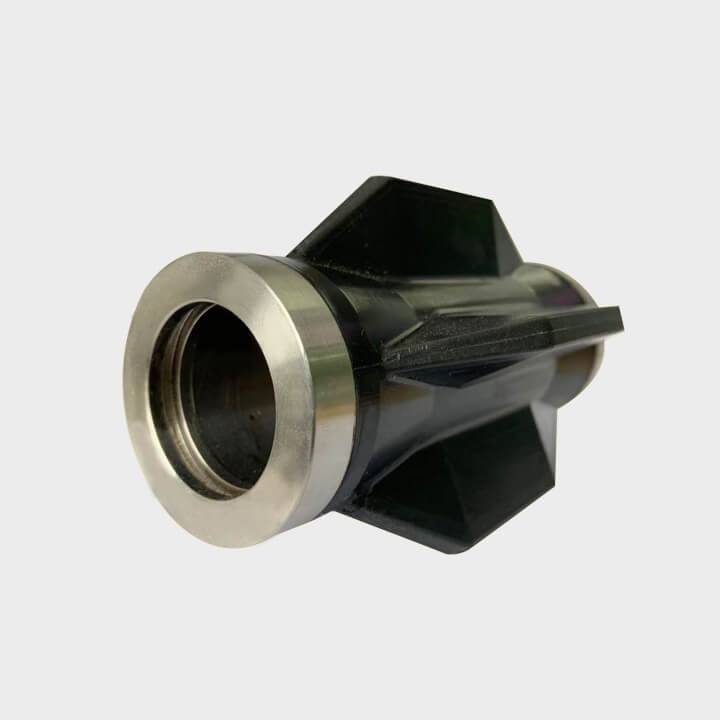

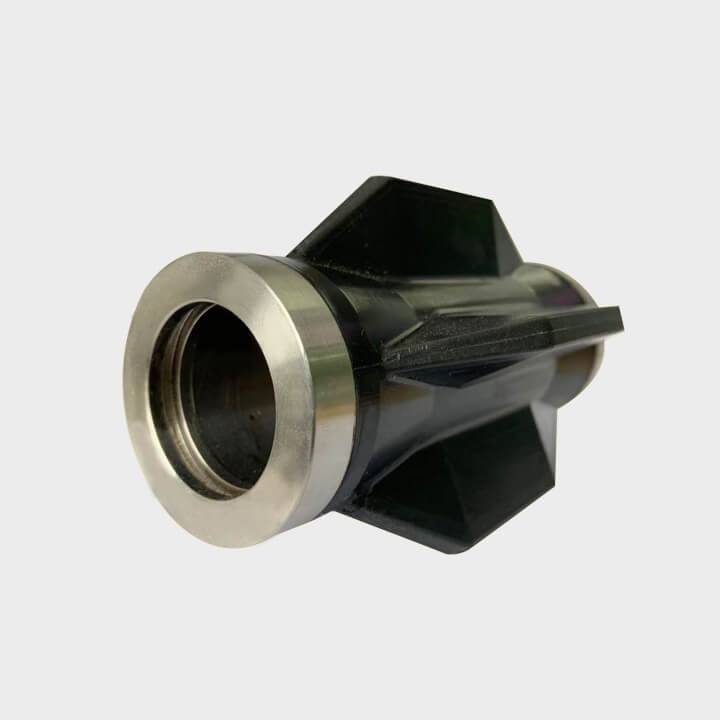

Radial Bearing

TC bearing adopts the general sintering process of ordinary high temperature furnace, unique sintering process

Strictly control the quality of raw materials to ensure that cemented carbide and tungsten carbide meet the standards of use. -

Nozzle

Our company produces various nozzles with different structures to meet the needs of domestic and foreign customers for bit nozzles.

-

Transmission Section

The transmission assembly, which is attached to the lower end of the rotor, transmits the rotation and torque generated by the power section to the bearing and drive shaft. It also compensates for the eccentric movement of the rotor’s nutation and absorbs its downthrust.

Rotation is transmitted through the transmisson shaft, which is fitted with a universal joint at each end to absorb the eccentric motion of the rotor. Both universal joints are packed with grease and sealed to extnd their life.

-

PDC Cutter

Polycrystalline diamond (PDC), also known as man-made diamond and synthetic diamond) is engineered to deliver superior cutting performance and maximize the downhole performance of the PDC bit.

-

Package Services

Based on the well profile, geological stratification and lithology data, the design features of the downhole motors and the previous application results, DeepFast will make a design of drilling tools for this formation by computer softwares.

-

Factory wholesale Reamer - Two-Stage and Two-Speed Drilling Tools – DeepFast

Features Two-Stage and Two-Speed Drilling Tools can fully utilize the technical advantages of PDC bit efficient rock breaking and further improve its mechanical drilling rate in low permeability formations. From the principle of bit breaking rock, the two-stage two-speed drilling tool is no different from the conventional PDC bit. The main difference between the two is that the specific method of rock breaking is different. The two-stage two-speed drilling tool has two drill bits with differe...