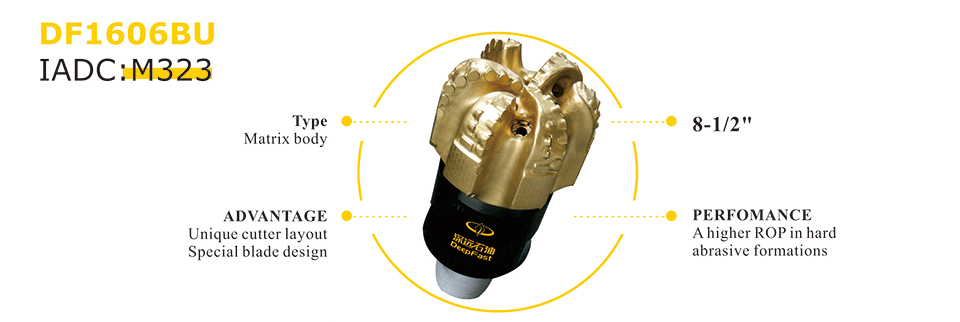

OEM manufacturer Pdc Bit 8 1/2″ 7 Blades - Matrix Body PDC Drill Bit – DeepFast

OEM manufacturer Pdc Bit 8 1/2″ 7 Blades - Matrix Body PDC Drill Bit – DeepFast Detail:

Design for higher ROP in drilling deeper and harder formations, PDC drill bit always drills from ground to bottom directly with less or even a single run, saving large amount of drill time and cost .

Differ from tricone bit, PDC drill bit runs with lower WOB but Higher RPM, so it usually works with downhole motor to pick up rotating speed.

The performance of PDC drill bit depends a lot on PDC cutters, we provide unique solution to specific requirement on varied formations.

|

Bit Size |

8-1/2″ |

9-1/2″ |

12-1/4″ |

|

Number of Blade |

6 |

6 |

6 |

|

Main Cutter Size |

5/8″(16mm) |

5/8″(16mm) |

5/8″(16mm) |

|

Main Cutter Qty |

34-39 |

43-50 |

52-59 |

|

Gauge Length |

2.0″(50.8 mm) |

2.5″(63.5 mm) |

3.0″(76.2 mm) |

|

Nozzle Qty(type) |

6SP |

7SP |

8SP |

|

Junk Slot Area |

15.9in2 (102.6cm2) |

18.4in2(118.7cm2 ) |

42.0in2 (271cm2) |

|

Make-up Length |

13.2″(335.3mm) |

14.3″(363.2mm) |

14.5″(368.3mm) |

|

API connection |

4-1/2″ Reg. |

6-5/8″ Reg. |

6-5/8″ Reg. |

Matrix Bits are optimal solution for well drilling where use of ordinary steel bits lead to their rapid erosive wear.

Manufacturing a matrix bit body from a composite material based on tungsten carbide allows bits to drill in high abrasive formations using weighted drilling mud.

Specially selected material compositions provide high reliability and durability for continuous bit runs.Improved designing and manufacturing technologies make it possible to produce a wide range of drilling tools.

Matrix tools can be multiply subjected to restoration. This feature allows increasing life-time of tools and achieve higher rates.

Introduction:

Matrix Body PDC Drill Bit is suitable for medium hard and hard formations with optimized crown profile and cutters layout. It can achieve better performance in deep intervals. Long service life and high performance help reduce the drilling cost.

Features

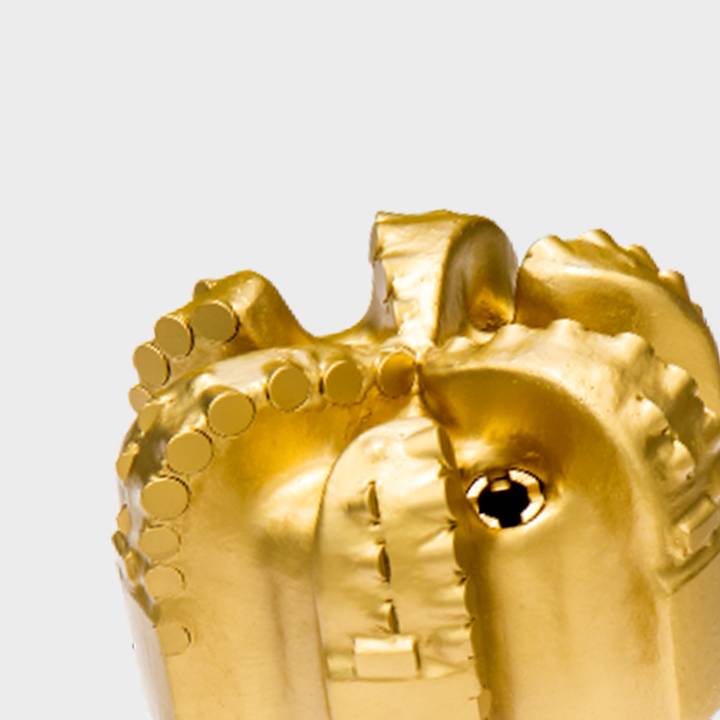

Durasef Gauge: Super strong material promotes gauge wear resistance to enhance long lifetime.

Hydraulics: The movement and cooling of cuttings can be optimized by the hydraulic design that matches the chip quantity and displacement of each blade

Technology

Unique Blade Design: Importing exclusive cutting teeth and unique curved blade design improve the ability of drilling in hard interlayer.

The formula of matrix powder: independent intellectual property rights and advanced sintering technology have made the mechanical properties of matrix reach the international advanced level. The blade of the matrix drill can be designed to be deeper and narrower. It can completely satisfy the complex drilling operation in the well.

Product Specifications:

| IADC code | M323 |

| Number of Blade | 6 |

| number of nozzles | 5 |

| Total Cutters | 36 |

| Main Cutter Size | 1/2″(16mm) |

| Gauge Length | 2.0″(50.8cm) |

| Junk Slot Area | 15.9in2 (102.6cm2) |

| API connection | 4-1/2” Reg. |

Recommended Operating Parameters:

| Flow rate | 100~350 GPM / 21~35 L/S |

| Rotary Speed | 60~300 RPM |

| Weight on bit | 3~15Klbs / 20~110 KN |

| Mix Weight on bit | 20Klbs / 90 KN |

One Matrix Body PDC Bit Drilled Successfully in Xujiahe Layer

in Sichuan China.

CHALLENGES

In order to reduce the quantity of PDC Bit drilling in Xujiahe Layer in the Sichuan of China. Chinese bit manufactures try to design enhanced PDC bit to drill by ONE BIT.

SOLUTION

Deepfast offer its own designed

Matrix Body PDC Bit 12 1/4 DF 1605BU to increase the lifetime of drilling bit.

RESULTS

It sets new Roprecord of 7.13

The bit drilled successfully in the layer by only One Bit

Overview

In the Sichuan of China. the formation is medium-hard but abrasive, Great Wall Drilling Company of CNPC try to increase drilling footage and reduce the quantity of PDC bits in Xujiahe Layer. In this layer, the depth is from 1300 to 1900 and the compress strength is 12000PSI-16000PS1. Deefast designs the Matrix Body PDC Bit 12 1/4″ DF1605BU for this project.

Technology Advantage

The Matrix Body PDC Bit 12 1/4″DF 1605BU is an improved bit specially developed for increasing the strength and lifetime of drill bits. The formula of matrix powder with independent intellectual property rights and advanced sintering technology have made the mechanical properties of matrix reach the international advanced level. Super strong material promotes gauge wear resistance to enhance long lifetime. It has the characteristics of high rotary speed stability and long service life while drilling.

Performance

It achieves best ROP of 10.61 m/h, and the average of ROP of five bits is 7.13 m/h.

All of bits drilled successfully in the layer by only One Bit.

12 1/4″ PDC Bit Drilling Performance

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for OEM manufacturer Pdc Bit 8 1/2″ 7 Blades - Matrix Body PDC Drill Bit – DeepFast , The product will supply to all over the world, such as: Greenland, Mongolia, Botswana, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.