Low MOQ for Polycrystalline Diamond Compact Bit - Downhole Motor – DeepFast

Low MOQ for Polycrystalline Diamond Compact Bit - Downhole Motor – DeepFast Detail:

We offer you a wide range of products with various technical specifications for every application, including custom requirements.

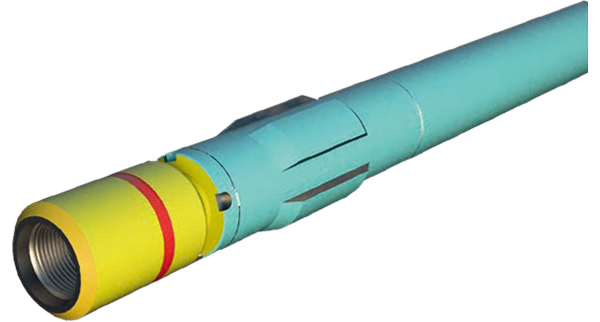

Drilling Motors

Our motors are provided in different configurations for specific needs.

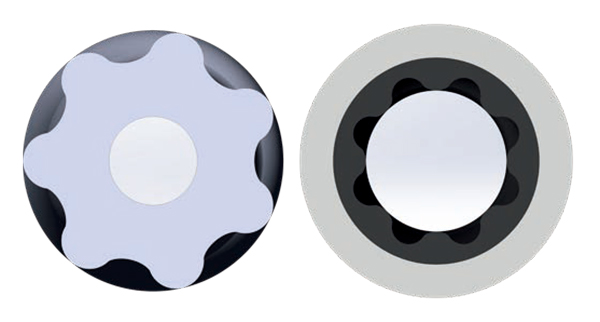

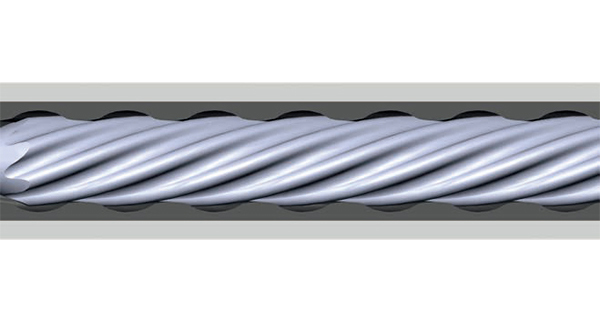

Rotors and Stators

We provide the universal parts of rotors and stators in different lengths and sizes.

The heart of our motors, power sections are available in many configurations. Ours are suitable for water-based muds (WBMs), oil-based muds (OBMs), agitators, and other applications.

Shock Tool system

The SGDF Shock Tool System can reduce friction and dramatically improve weight transfer by producing gentle oscillation, thus improving the quality of the wellbore in less complex applications. The SGDF Shock Tool System increases the drilling efficiency of any drilling system in which friction is an issue.

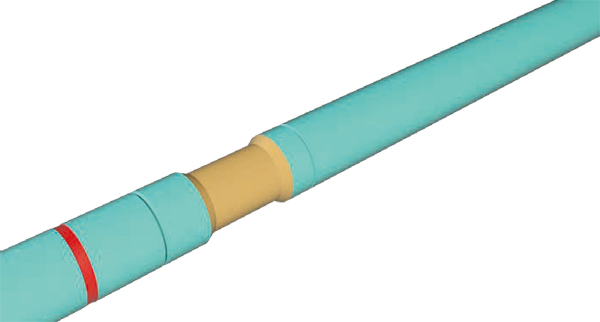

Centering Elements

Centering elements are available in any design and configuration.

Our motto: “We always find solutions” —

even in extreme situations and challenging conditions

Features and Technology

We perform elastomer development and manufacturing in cooperation with academic and scientific institutes in Europe for advanced solutions. The supply chain of steel manufacturers with excellent national and international reputations allows DeepFast to bring highly durable motors to the market. The careful selection of special material grades for DeepFast motors provides the needed performance.

The products of DeepFast unites state-of-the-art German elastomers, geometry design, and quality control. DeepFast provides the stator available with NBR and HNBR elastomers based on the mud type. Every step of stator manufacture and material process is carefully monitored to ensure the high-quality stator.

DeepFast rotors are made of high-grade steel and precision-milled on sophisticated milling equipment. To match the demands of specific project applications, DeepFast rotors are precisely contoured to various lengths. The rotors are custom-selected to fit each drilling application. DeepFast rotors are chrome-plated by German technology. For salty mud with a high chloride content, DeepFast can provide carbide coated rotors.

1.High Torque

At least 50% more torque than ordinary downhole motors.

2.Long Lifetime

At least 100% improved performance compared to that of ordinary downhole motors owing to five-axis milling machines or rotors and stators.

3.High Temperature Resistance

Up to 175°C in harsh conditions.

4.Applicable in OBM

Diesel, crude oil, technical white oil. Suitable for circulation.

Product Specification

| Items |

Matric |

Inch |

| Size |

175mm |

6.9in |

| Applicable wellbore size | 8 3/8”~9 7/8” | |

| Lobes |

7:8 |

|

| Stage |

4.5 |

|

| Length |

9789mm |

385.4in |

| Weight |

1400KG |

3086 lbs |

| Top Thread Connection | NC 50 BOX | |

| Bottom Thread Connection | NC 50 PIN | |

| Recommend Torque |

43.5~48kN.m 31389.6~34636.8 ft-lbs |

|

| Highest Temperature Resistance |

120℃ |

|

Operation Parameter

| Items |

Matric |

Inche | |

| Flow Rate Range | 1000~2500 L/M | 265~660gpm | |

| Rotary Speed | 42~104 RPM | ||

| Max Diff Pressure | 6MPa | ||

| Max Diff Torque |

14620N.m |

10790 ft-lbs | |

| Working Diff Pressure | 4.5 MPa | ||

| Working Torque |

10900 N.m |

8045 ft-lbs | |

| Recommend WOB |

8~12 T |

17636~26455 lbs | |

| Max WOB |

20 T |

44092 lbs | |

| Max Power | 122.5Kw | ||

| Max Lifting Weight |

160T |

352740 lbs | |

| Plugging Material Requirement | Diameter<7mm | ||

| Chloride Content | <50000 PPM | ||

| Recommend Oil-Based Mud Aniline Point | ≥70℃ | ||

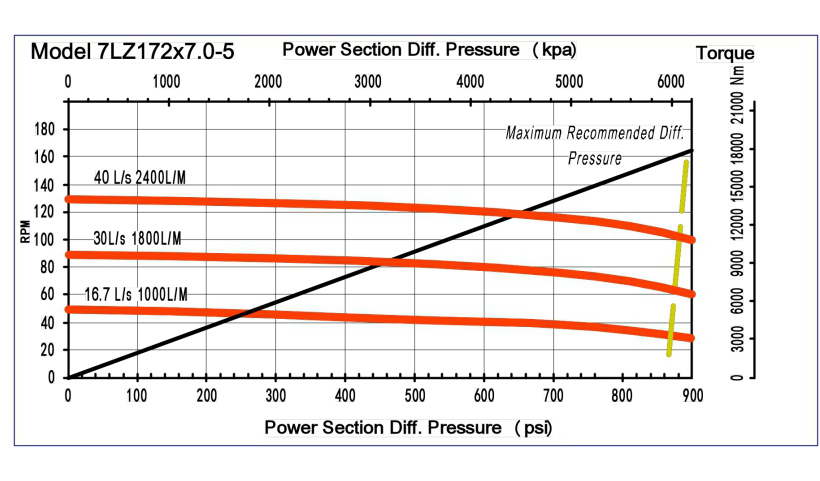

Power Section Diff Pressure

Product detail pictures:

Related Product Guide:

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Low MOQ for Polycrystalline Diamond Compact Bit - Downhole Motor – DeepFast , The product will supply to all over the world, such as: Kenya, Macedonia, Cologne, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.