factory customized Small Diamond Core Drill Bits - Steel Tooth Tricone Bit – DeepFast

factory customized Small Diamond Core Drill Bits - Steel Tooth Tricone Bit – DeepFast Detail:

Design for higher ROP in drilling deeper and harder formations, PDC drill bit always drills from ground to bottom directly with less or even a single run, saving large amount of drill time and cost .

Differ from tricone bit, PDC drill bit runs with lower WOB but Higher RPM, so it usually works with downhole motor to pick up rotating speed.

The performance of PDC drill bit depends a lot on PDC cutters, we provide unique solution to specific requirement on varied formations.

Introduction:

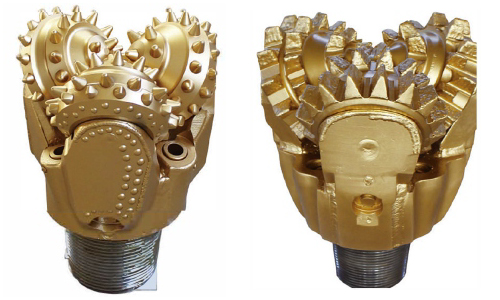

TCI Tricone Bit is suitable for soft formation with low compressive strength and high drillability, such as mudstone, gypsum and soft limestone, etc. Tricone bit with high strength toughness of carbide tooth reduces rate of gear broken and with high-performance wear resistant materials improve the wear resistance and service life of the bit.

Features

1.Nozzle:These nozzles are much sturdier and provide greater flow capacity and maximize fluid distribution to the cones.

2.G-Gauge protection: more tungsten carbide inserts are placed in the gauge to reduce the wear in the abrasive formation. It can protect gauge and increases the stability and life of the bit.

3.Bearing Structure: High precision journal bearing with two thrust faces. Ball locked cone. Hardfaced head bearing surface. Cone bearing inlaid with friction reducing alloy and then silver-plated. Abrasion resistance and seizure resistance of the bearing are improved, and suitable for high rotary speed.

Technology

1.Motor hardfacing: Tungsten carbide particle hardfacing is applied liberally along the shirttail and extended up the leading edge of the bit leg for additional protection in high-speed, directional or abrasive applications

2.Seal and Lubrication: The bearing seal is adapting the high quality HNBR O-ring. The best seal compression and the radial seal structure can enhance the seal performance. The compensation system and the high quality bit grease can limit pressure differential, and greatly increase the lubricating reliability.

| Bit Size | IADC Code | API Connection | Recommended Parameters | ||

| in | mm | Rotary Speed (rpm) | Weight on bit (KN) | ||

| 6″ | 152.4 | 637 | 3 1/2 Reg | 50~-100 | 50~150 |

| 8 -1/2” | 215.9 | 517 | 4-1/2’’API REG | 60~-120 | 90~200 |

| 9 -1/2” | 241.3 | 537 | 6-5/8’’API REG | 50~120 | 120~260 |

| 12-1/4” | 311.2 | 537 | 6-5/8’’API REG | 60~120 | 150~300 |

Air Drilling Bits

Feature and Applications

In hard formation with less water content,formation with serious leakage or with low pressure,in order to achieve higher ROP.air drilling process is usually adopted.The series bit foe air drilling which has structure features of center jet hole and enhanced head O.D.This bit with these features is suitable for drilling at air drilling application to increase observably ROP and life of the bits.

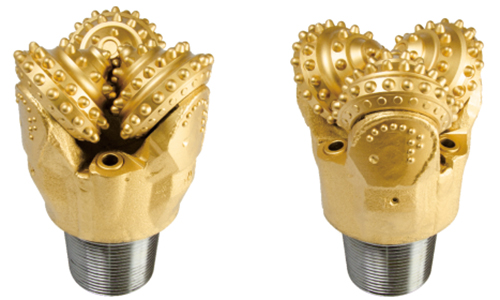

DFJ Series Metal Sealed Bearing Bit

Feature and Applications

Metal sealed with journal bearing. Hardfaced head bearing surface,inner hole of cone is silver-plated. The load capacity and sei-zure resistance of the bearing is greatly improved. High wear re-sistance and excellent cutting ability of the insert bit are given full play by using carbide compact of high strength and high toughness in combination with optimized compact numbers and rows,the exposure height and special shaped compacts.

DFX Series Rubber Sealed Bearing Bit

Feature and Applications

Journal bearing.Hardfaced head bearing surface.inner hole of cone is silver-plated.The load capacity and seizure resistance of the bearing is greatly improved.0 ring seal is made of the more wear resistance high saturated buna-N with the increased seal section and precisely designed sealing flflange in the cone sealing area increased the reliability of the seal.

KXSeries Mining Tricone Rock Bits

The main structure features:

This series applies flfloat ring that have high strength and processing precise,and prolong the bit bear life.

New designing lubrication reservoir structure enhances lubrication oil compensation ability of bit bear,and reduces wear of bear pair.

Gauge protection structure of raised design leg reduces friction from the back of leg to well wall,and gains high drilling effificiency.

Gauge teeth added on the cone enhances ability of cutting well wall.

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for factory customized Small Diamond Core Drill Bits - Steel Tooth Tricone Bit – DeepFast , The product will supply to all over the world, such as: Russia, Juventus, Belgium, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.