Mill Shoe

Design for higher ROP in drilling deeper and harder formations, PDC drill bit always drills from ground to bottom directly with less or even a single run, saving large amount of drill time and cost .

Differ from tricone bit, PDC drill bit runs with lower WOB but Higher RPM, so it usually works with downhole motor to pick up rotating speed.

The performance of PDC drill bit depends a lot on PDC cutters, we provide unique solution to specific requirement on varied formations.

Introduction

It is suitable for grinding the bottom hole in the casing.

Features

1.Special Design: It has the flat-top crown-shaped high-density natural diamond tooth.

2.High-quality natural diamond: it can increase the speed and prolong the life of the mill shoes.

Specifications:

|

IADC code |

M813 |

|

Total flow area |

0.7 in2 |

|

Cutting Structure |

Natural Diamond 12pcs/ct. |

|

Standard gauge length |

1.0"~2.0"(25.4mm~50.8 mm) |

|

API connection |

2-3/8"API Reg. |

Recommended Parameters:

|

Flow rate |

10~16 L/S |

|

Rotating speed |

60~180rpm |

|

Drilling pressure |

9~40 KN |

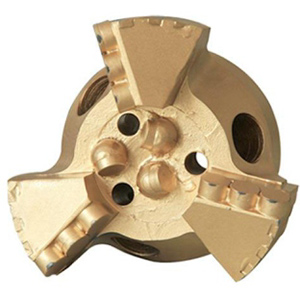

The drag bit has a central core, with at least three, but as many as eight, triangular cutting surfaces. The cutting edges of all or at least half of the total number of the bit's teeth face the forward end of the bit. Any other cutting edges face the drill string, so that the bit may be used while moving in either direction.

Designed for use in soft formations such as sand, clay or some types of soft rock. And drag bits made with tungsten carbide teeth can improve the performance in hard rock formations.